SLT Co., Ltd. has already been recognized for its technology in various industrial sites.

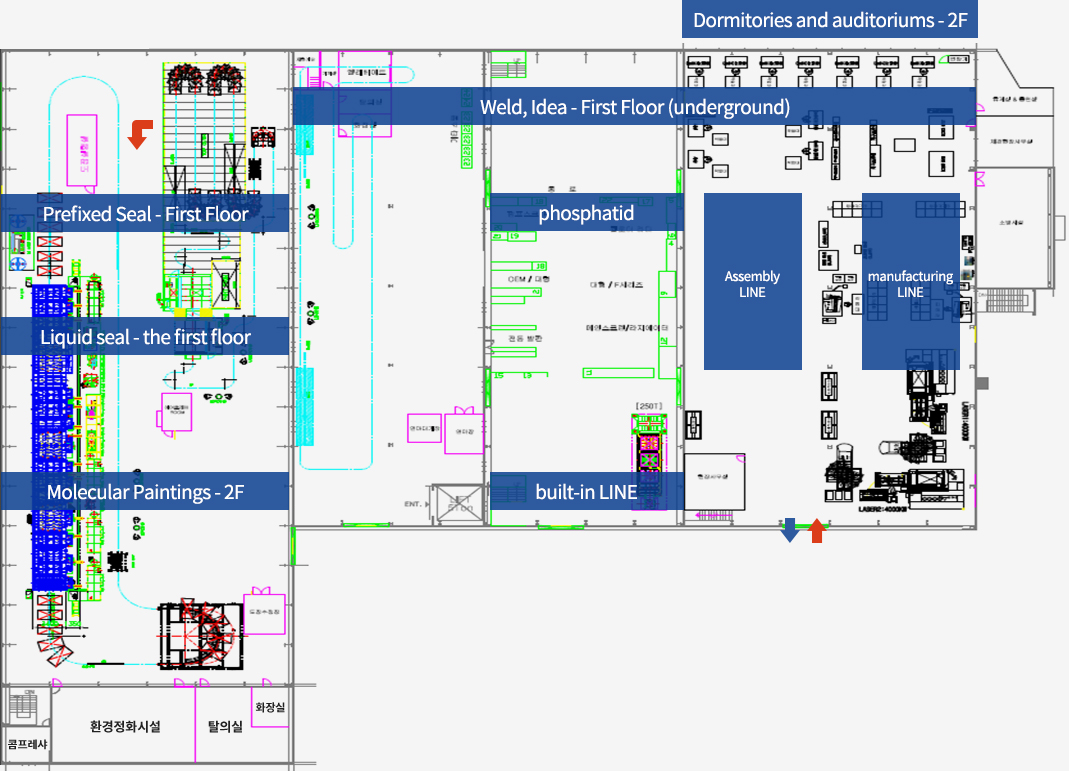

The land of SLT Co., Ltd. is 3500 pyeong / 3200 pyeong.

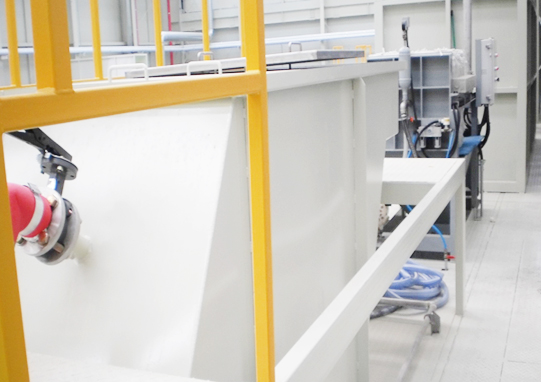

Production, pre-treatment coating (electrodeposition), finished coating (liquid, powder)Equipment and facilities are prepared to proceed.

We secured competitiveness through ONE STOP of metal products considering design, production, quality, and logistics.

First-in, first-out

Insufficient sanding work in the assembly part of the HANGER RAG, electricity failure occurs

Water is filled between the GAPs on the product welding area and the product is preheated for post-processing.

In order to eliminate the quality problem of the welding area, slag, carbonization, etc. on the surface are removed.

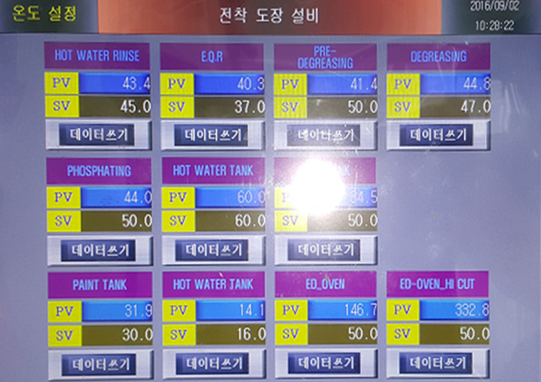

Saponification process to remove oil foreign substances on the product surface

Process for leveling the surface by removing oily foreign substances on the surface of the product (applied to ultrasonic cleaning)

Process for removing degreasing liquid and removing foreign substances on the product surface

This is to remove the degreasing liquid and remove foreign substances on the product surface and is a process for leveling the product surface.

This is a preparation process for forming a chemical conversion film, and a titanium salt colloidal process on the product surface for enhanced corrosion resistance.

Process to form zinc phosphate coating layer through free acid and computation on the surface for enhanced corrosion resistance

This is a process to remove residual film sludge on the product surface. It is a process to remove residues that may be generated during electrodeposition coating.

This is a process for leveling the entire surface of the entire product by removing residual film sludge on the product surface.

Final process to remove the conductive impurities and residual film impurities that may occur when the product surface is energized

This is a process to remove the residual moisture of the product to smooth the energization during electrodeposition.

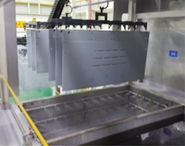

Process of depositing a coating film on the surface of the product by electric force

A device that circulates through the UF device as a process to remove excess precipitated paint

This is a process of removing foreign substances in the remaining paint of the product and neutralizing the weakly acidic liquid on the product surface.

This is a process to cure corrosion resistance and hardness by curing the coating film deposited by electrodeposition coating.

Process for removing degreasing liquid and removing foreign substances on the product surface

SLT Co.,Ltd | CEO : kyunghwan Lee | Address : Address: 108-31 Bancheon san up-ro, Eonyang-eup, Ulju, Ulsan, Korea

Phone : +82-052-261-2280 | Business registration number: 610-81-92252

Copyright © SLT Co.,Ltd. All rights reserved.

company : Slt.Co.,Ltd | President: kyunghwan lee | address : 108-31, Bancheonsaneop-ro, Eonyang-eup, Ulju-gun, Ulsan, Republic of Korea | tel : 052-261-2280

Copyright © Slt.Co.,Ltd All rights reserved.